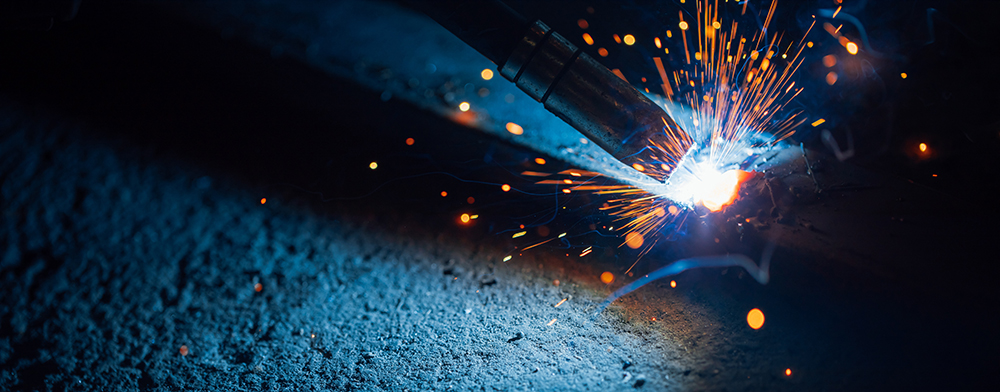

In celebration of National Welding Month this April, the Florida-based team at Double R Manufacturing is listing a wide array of things to know about welding. If you have ever wondered what welders do, this is the list for you:

- As highly trained workers, welders are responsible for keeping the U.S. running with metal parts and products affecting all facets of our daily lives at home and at work.

- Skilled welders can create, install, and repair metal products by using heat to melt and fuse metal pieces and parts together.

- There is no shortage of materials for welders to fuse, including steel, stainless steel, sheet metal, brass, aluminum, or even thermoplastics.

- As part of the fabrication process, the welding technique can allow artisans to create products and equipment that are totally unique.

- From a blowtorch to an electric arc, certified welders know how to use an array of tools to join metal pieces together for total functionality and strength.

- Often, for new product designs and assembly, welding is performed in conjunction with cutting, shearing, punching, bending, folding, stamping, pressing, beading, and machining.

- Welding Certificate Programs include required courses and hands-on instruction. Different certifications range from six months to two years of training.

- There is a great demand and need to train new welders. The American Welding Society predicts we could have a shortage of 400,000 welders by the year 2024.

- As a true artform, professional welders and metal fabrication experts can provide customized pieces that outshine and outlast flimsy, assembly-line items.

- Whether complex products, artwork, equipment repairs, or new designs, the welders at Double R Manufacturing can offer custom solutions to complete your unique project.

Customized Metal Equipment and Durable Products

In addition to professional welding, Double R Manufacturing’s engineers and craftsmen have honed extraordinary skills in sandblasting, waterjet cutting, powder coating, and other techniques. Customers trust us for customized products and equipment like entrance gates, fences, railings, stairs, barn equipment, and breeding stalls. The list also includes custom signage, tables, bars, benches, carts, trailers, grills, wall art, yard art, and other specialty pieces.

Whether we work with an individual or a corporation, one piece or thousands, we enjoy bringing your product visions to life. Call Double R Manufacturing today at (800) 813-3361 to learn more.