It is easy to find metal fabrication services for nearly any project. From metal restoration for historic pieces to mass production of essential products – there are manufacturing options and machining experts to help bring your visions to life.

With Florida-based facilities delivering services to customers nationwide, Double R’s team of skilled specialists are explaining how today’s technologies and tools can customize structures with the sturdiest metals, steel, aluminum, and other materials.

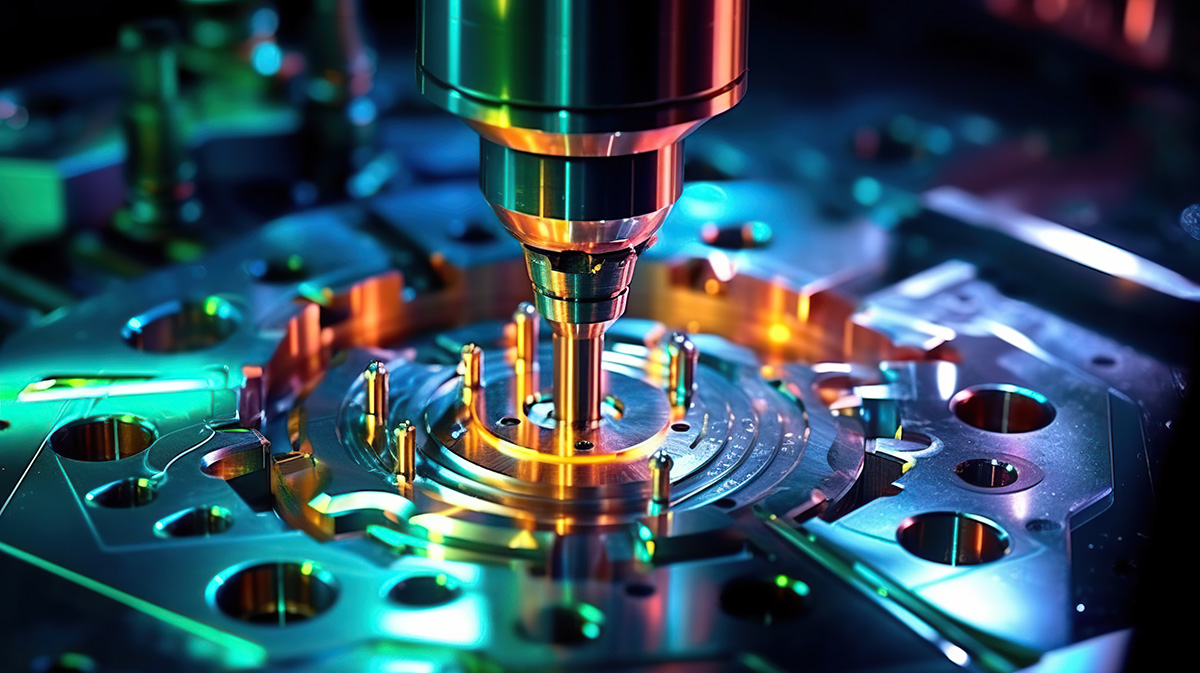

CNC Machining, Welding, and Manufacturing Processes

Double R has many manufacturing processes to transform raw materials into infinite possibilities for property owners and commercial customers. CNC machining and welding are among the most important specializations needed to create customized items.

Corporations, ranchers, and homeowners alike can find metal fabrication services to fit any needs for welding as well as cutting, bending, folding, casting, or molding. Double R also uses techniques like sandblasting and waterjet cutting for special projects.

Depending on the desired results, customers also benefit from Double R’s expertise in Aluminum GTAW (TIG). Other projects may include GMAW, FCAW, and GTAW welding on steel and stainless steel.

Advanced Technologies, One-Off Items, and Mass-Production

As talented specialists, Double R’s designers have the advanced technologies, skillsets, materials, equipment, and assembly processes to provide one-off items or mass-production. Other manufacturers can’t compete in quality, materials, colors, styles, sizes, and specifications.

At Double R, our manufacturing and machining experts utilize CNC plasma tables, press brake, and welding equipment to build fixtures and any number of items. It is a complete source for custom projects, assembly processes, and high quantity runs with express production.

Yes, tools and technologies have advanced during our decades of experience, but our creative experts continue to find metal fabrication to be a hands-on artform.

Manufacturing and Customizing Metal Products and Equipment

In terms of manufacturing, customers can find metal fabrication services most useful for customizing metal products and equipment. Double R’s best work includes signage, gates, fencing, railings, stairs, barn equipment, stalls, trailers, truck conversions, custom BBQs, tables, bars, benches, carts, bumpers, small bridges, ramps, toolboxes, roof supports, shelving, wall art, racks, storage boxes, hooks, marine products, and countless items.

From cutting and welding, to assembling and delivering across America, Double R provides a one-stop-shop for metal products and equipment.

Whether we work with an individual or a corporation, one piece or thousands, we enjoy bringing your product visions to life. Call Double R Manufacturing today at (800) 813-3361 to learn more.