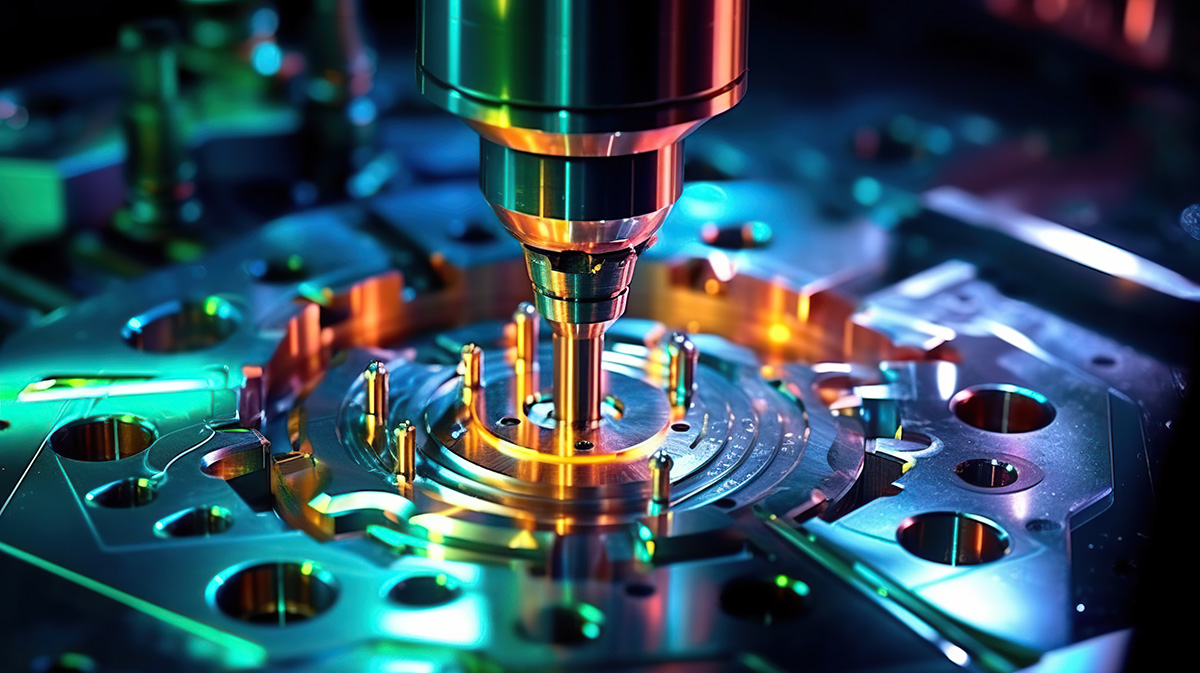

In today’s competitive manufacturing landscape, precision and reliability aren’t just advantages—they’re necessities. At Double R Machining, our subsidiary company specializing in CNC machining services, we’ve built our reputation on delivering exceptional quality and dependable results that keep our customers coming back project after project. Whether you’re developing prototypes, producing critical components, or need precision parts manufactured to exact specifications, our CNC machining capabilities provide the accuracy and consistency your projects demand.

The Foundation of Modern Manufacturing

Computer Numerical Control (CNC) machining represents the pinnacle of precision manufacturing technology. By utilizing computer-controlled machine tools, CNC machining eliminates human error while achieving tolerances that would be impossible with manual machining methods. At Double R Machining, our state-of-the-art CNC equipment allows us to consistently produce parts with tolerances measured in thousandths of an inch, ensuring every component meets your exact specifications.

This level of precision is particularly crucial in today’s manufacturing environment, where component compatibility, performance reliability, and quality consistency can make the difference between project success and costly failures.

Prototyping: Bringing Ideas to Life

One of the most valuable applications of CNC machining is in the prototyping process. At Double R Machining, we understand that prototyping is where innovation takes its first tangible form. Our CNC capabilities allow engineers, inventors, and product developers to quickly transform concepts into functional prototypes that can be tested, evaluated, and refined.

Rapid Prototype Development

CNC machining excels in rapid prototyping because it can produce functional parts directly from digital designs without the need for expensive tooling or lengthy setup processes. This means you can have physical prototypes in your hands within days rather than weeks, accelerating your development timeline and allowing for faster iteration cycles.

Material Flexibility for Testing

Prototyping often requires testing with the actual materials intended for production. Our CNC machining capabilities work with a wide range of materials, from aluminum and steel to exotic alloys and engineering plastics, ensuring your prototypes accurately represent the performance characteristics of your final product.

Design Validation and Refinement

CNC-machined prototypes provide the dimensional accuracy and surface finish quality needed for thorough design validation. This precision allows you to identify potential issues, test fit and function, and make necessary refinements before moving to full production.

Production Machining Excellence

Beyond prototyping, Double R Machining serves as a trusted partner for production machining needs across various industries. Our production capabilities are designed to deliver consistent quality whether you need a single precision component or thousands of identical parts.

Custom Component Manufacturing

Many applications require components that simply aren’t available as standard products. Our CNC machining services excel at producing custom components that meet specific dimensional, material, and performance requirements. From one-off specialty parts to custom modifications of existing designs, we have the expertise to deliver solutions that fit your exact needs.

Replacement Parts and Obsolete Component Recreation

When critical equipment fails and replacement parts are no longer available, CNC machining provides the solution. We can reverse-engineer obsolete components and manufacture exact replacements, often improving upon the original design while maintaining full compatibility.

Small to Medium Production Runs

For production quantities that are too small for automated manufacturing but too demanding for manual methods, CNC machining provides the perfect solution. We specialize in small to medium production runs that require precision and consistency without the overhead of large-scale manufacturing processes.

Industries We Serve

Double R Machining’s precision CNC capabilities serve a diverse range of industries, each with unique requirements and demanding standards:

Aerospace and Defense

The aerospace industry demands components that meet stringent specifications and perform reliably under extreme conditions. Our CNC machining capabilities meet the precision and quality standards required for aerospace applications.

Medical Device Manufacturing

Medical device components require exceptional precision and surface finish quality. Our CNC machining services can produce components that meet medical industry standards and regulatory requirements.

Automotive and Transportation

From prototype components for new vehicle designs to custom parts for specialty vehicles, our CNC machining capabilities support the automotive industry’s demanding requirements.

Industrial Equipment and Machinery

Manufacturing equipment and industrial machinery often require custom components or precision replacement parts. Our CNC machining services keep industrial operations running smoothly.

Energy and Oil & Gas

The energy sector requires components that can withstand harsh operating conditions while maintaining precise tolerances. Our CNC machining capabilities meet these demanding requirements.

The Double R Machining Quality Difference

What sets Double R Machining apart in the competitive CNC machining industry is our unwavering commitment to quality and reliability. This commitment is reflected in every aspect of our operation:

Experienced Craftsmen and Programmers

Our team combines traditional machining expertise with modern CNC programming skills. This unique combination ensures that every job benefits from both technical precision and practical manufacturing knowledge.

Advanced Equipment and Technology

We invest in state-of-the-art CNC equipment and regularly update our capabilities to stay at the forefront of machining technology. This commitment to modern equipment ensures we can handle the most demanding projects with confidence.

Rigorous Quality Control

Every component we produce undergoes thorough inspection to verify dimensional accuracy, surface finish quality, and adherence to specifications. Our quality control processes ensure consistent results across all production runs.

Dependable Delivery

In manufacturing, timing is critical. Our reputation for dependable delivery means you can count on us to meet your project deadlines without compromising quality.

Material Expertise

CNC machining success depends heavily on understanding material properties and selecting appropriate cutting strategies for each application. Double R Machining works with an extensive range of materials:

Aluminum Alloys: Excellent for prototyping and production applications requiring strength-to-weight optimization Steel and Stainless Steel: For applications requiring strength, durability, and corrosion resistance Titanium: For aerospace and medical applications demanding high strength and biocompatibility Engineering Plastics: For applications requiring specific material properties or electrical insulation Exotic Alloys: Specialized materials for unique application requirements

Partnership Approach

At Double R Machining, we view every project as a partnership opportunity. We work closely with our customers to understand not just what they need, but why they need it. This understanding allows us to provide valuable input on design optimization, material selection, and manufacturing approaches that can improve both component performance and cost-effectiveness.

Our engineering support extends beyond simple manufacturing to include design for manufacturability recommendations, cost optimization suggestions, and alternative approaches that might better serve your project goals.

Precision You Can Trust

In an industry where precision is measured in thousandths of an inch and quality cannot be compromised, Double R Machining has earned its reputation as a trusted partner for demanding CNC machining projects. Our combination of advanced technology, experienced craftsmen, and unwavering commitment to quality ensures that every component we produce meets the highest standards.

Whether you’re developing the next breakthrough product, need critical replacement components, or require precision parts for demanding applications, Double R Machining provides the expertise, capability, and reliability you need to succeed.

Ready to Experience the Double R Machining Difference?

Discover how precision CNC machining can support your next project. Contact Double R Machining today to discuss your requirements and learn how our commitment to quality and dependability can contribute to your success.

From initial prototyping through full production, we’re ready to be your trusted partner in precision manufacturing.